Quality thanks to precision

Paper is a hygroscopic material that tends to equalise humidity with the environment. The relative humidity therefore plays a decisive role in the printability of the paper during storage. Conditioning the paper in accordance with the manufacturer‘s instructions is an important prerequisite for high-quality printing results.

Fluctuations in relative humidity before and during the printing process can lead to undesirable effects and even costly machine failures.

- Register inaccuracies due to dimensional changes (up to 2 mm on printed sheets) and unevenness of the substrate (e.g. corrugation, curling or dust)

- Extension of the printing process and further processing due to drying times that are not adhered to (possibly even unusable result)

- Paper jam or misfeed caused by static electricity in the environment

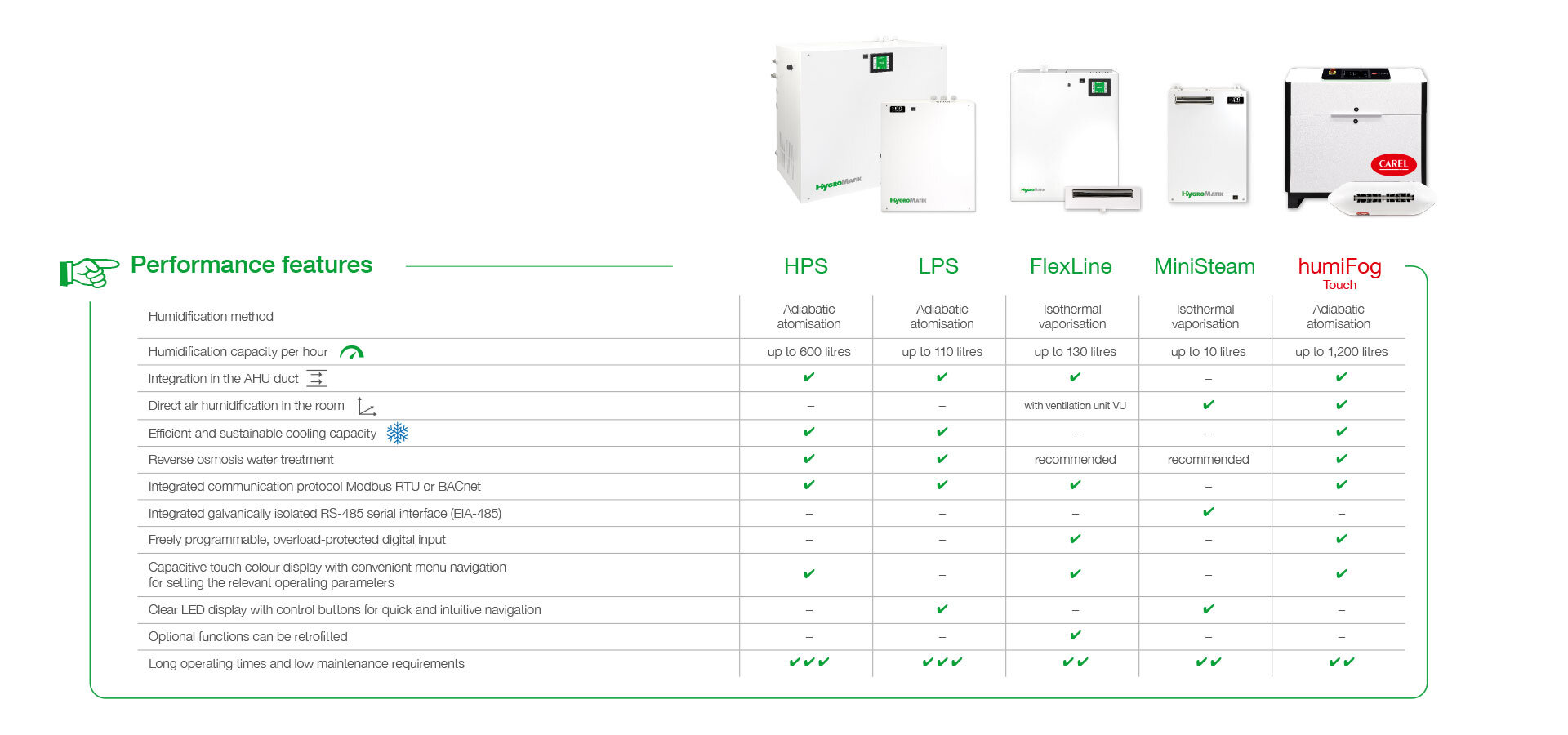

To avoid this, HygroMatik air humidification systems regulate the relative humidity in the storage and production facilities of the printing company precisely to the required values and keep them reliably constant - with positive effects on quality, efficiency and productivity.